In modern data centres, airflow efficiency is more than a best practice; it’s a strategic necessity. As cooling demands rise and operational margins tighten, every component within the server environment plays a role in shaping performance, energy use, and sustainability outcomes. Among the most understated yet essential tools in this ecosystem is the blanking panel.

These modular inserts are designed not only to close gaps in unused rack units but to actively prevent airflow recirculation, optimise cold aisle integrity, and support long-term energy reduction strategies.

To fully understand their value, it helps to look beyond the rack face and examine the complete lifecycle of a blanking panel, from engineered materials and snap-on design to repeated use and eventual recycling.

What Defines a Blanking Panel’s Lifecycle?

Every blanking panel moves through a four-phase lifecycle that contributes directly to a facility’s thermal efficiency and return on infrastructure investment: Manufacturing, Installation, Operational Use, and End-of-Life Management.

Manufacturing & Material Integrity

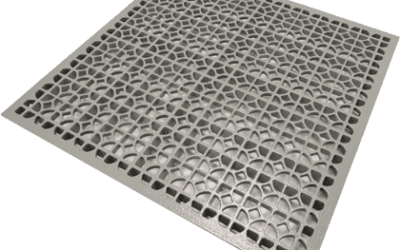

EziBlank panels are manufactured using UL-94 V0 flame-retardant ABS plastic, selected for its lightweight properties, high thermal resistance, and exceptional durability under repetitive use.

Each panel is shaped to align with industry-standard formats, including EIA-310-D and ETSI 21” rack systems, ensuring universal rack compatibility.

The material formulation not only enables a strong barrier against bypass airflow but also aligns with green design practices due to its recyclable properties.

Tool-Free Installation

Snap-on integration allows for tool-free installation in both retrofit and greenfield environments. Panels can be deployed within seconds, eliminating downtime and supporting flexible airflow zoning during MACs (Moves, Adds, Changes).

Operational Function

Once installed, blanking panels deliver three primary outcomes:

- They seal open RU gaps to direct airflow efficiently across active equipment

- They reduce reliance on CRAC units by preventing hot and cold air mixing

- They contribute to an organised and professional rack appearance

These operational benefits compound over time, offering a measurable contribution to thermal zone stability and system-wide performance.

Modular Reusability in Dynamic Racks

Data centre environments evolve, densities shift, hardware is replaced, and airflow plans must adapt accordingly. This is where the reusability of a blanking panel becomes a design advantage, not a cost.

EziBlank panels are engineered for thousands of installation cycles, supported by their durable ABS frame and optional Universal Catch accessories.

Where legacy screw-in solutions degrade with repeated handling, modular blanking panels preserve their structural integrity even after multiple redeployments. Their intuitive clip system enables repositioning without compromising airflow continuity or rack compliance.

This adaptability supports cold aisle containment strategies in multi-tenant data centres, colocation facilities, and edge environments where scalability is key.

Reusability and ROI in Practical Terms

The most compelling argument for reusable blanking panels lies in their cumulative return on investment. Consider a facility managing hundreds of racks over five years.

Replacing low-durability panels multiple times increases not only costs but labour input, disposal volumes, and operational inefficiencies.

In contrast, EziBlank’s modular panels, designed for tool-free redeployment across multiple rack builds, reduce panel replacement costs by up to 60% over three years.

When paired with intelligent airflow analytics through EkkoSense AI Optimization, facilities can fine-tune cooling outputs, resulting in additional savings on energy consumption and PUE metrics.

This synergy between hardware design and data-led optimization exemplifies the modern approach to infrastructure ROI. A panel becomes more than a passive insert; it’s a functional part of a scalable, energy-resilient strategy.

Sustainability Through Reuse: The Environmental Value of Blanking Panels

Sustainability in data centres is not limited to energy efficiency; it extends to material choices, lifecycle performance, and end-of-use considerations. Blanking panels that are built for long-term reusability provide significant environmental value when compared to single-use or brittle alternatives.

Each EziBlank panel contributes to lower landfill volumes by replacing the need for multiple disposable inserts over time. When a single panel can be repositioned across hundreds of RU configurations without degradation, the cumulative reduction in material waste becomes measurable.

Beyond longevity, material formulation matters. EziBlank’s use of UL-94 V0 flame-retardant ABS aligns with circular design standards by supporting recyclability at end-of-life. And because the panels are packaged using recyclable cardboard, the sustainability commitment extends from production to delivery.

Facilities working toward green certifications, whether under Uptime Institute, ISO 14001, or internal ESG frameworks, benefit from airflow solutions that are modular, non-destructive, and environmentally responsible.

Disposable vs Reusable Blanking Panels: A Lifecycle Comparison

When evaluating airflow panels from a total cost and performance perspective, material type and reusability define their long-term impact. The following table outlines key differences between disposable and EziBlank reusable panels across several critical dimensions:

| Feature | Disposable Panel | EziBlank Modular Panel |

| Material Composition | Thin polycarbonate or mixed plastics | Flame-retardant ABS (UL-94 V0) |

| Installation Method | Screw-in, non-reversible | Tool-free, ergonomic snap-on design |

| Reusability | Limited, typically one install | 1000+ repositioning cycles without wear |

| Cooling Performance | Inconsistent seal, prone to air leakage | Tight RU seal for precise airflow containment |

| ROI Over 3 Years | Higher replacement and labour costs | Up to 60% cost savings through redeployment |

| End-of-Life Options | Landfill or low-grade recycling | Designed for full recycling + take-back compatibility |

| Visual Integration | Varies, often mismatched | Uniform, professional aesthetic for high-visibility racks |

This comparison reinforces that tool-free modular design offers value beyond convenience; it strengthens operational efficiency, supports sustainability goals, and enables long-term cost control.

For environments that evolve frequently, such as high-density colocation centres or enterprise data halls, modular airflow solutions allow the infrastructure to adapt without compromising containment strategy.

Blanking Panel vs. Baffle: Choosing the Right Airflow Strategy

While often mentioned in the same breath, blanking panels and baffles serve different purposes in airflow containment and should not be viewed interchangeably.

| Aspect | Blanking Panel | Airflow Baffle |

| Function | Seals empty rack units to prevent recirculation | Redirects conditioned air or hot exhaust within structured airflow zones |

| Placement | Mounted within RU spaces in server racks | Installed overhead, underfloor, or within aisle ceilings/floors |

| Design Goal | Minimise leakage and maintain cold/hot aisle separation | Guide airflow direction toward or away from specific zones |

| Modularity | Fully modular and reusable with tool-free install | Typically fixed or adjustable based on airflow mapping |

| Use Case | Ideal for rack-level optimisation and cold aisle integrity | Best for broader facility airflow design and directional thermal control |

In high-density environments, both components may be deployed in tandem, with blanking panels maintaining front-to-back rack integrity while baffles manage vertical or lateral airflow paths.

When evaluating system-level airflow management, selecting the right containment components should align with the facility’s cooling strategy, rack density, and dynamic infrastructure plans.

EziBlank’s Tailor-Made Airflow Solutions can incorporate both elements into a cohesive design, customised to floor layout, thermal risk zones, and hardware access requirements.

How to Choose the Right Blanking Panel for Your Rack

Selecting a blanking panel is not a one-size-fits-all decision. Data centre environments vary in layout, rack standards, thermal demands, and operational fluidity.

To maintain airflow discipline while supporting rapid deployments or retrofits, each choice must align with both technical compatibility and infrastructure intent.

Here are the most important factors to consider:

1. Rack Size & Compliance

Begin by identifying rack dimensions. EziBlank panels are available for 19”, 21”, and 23” racks, and fit universally into EIA-310-D and ETSI-standard enclosures. Choose between 1U–10SU panel sizes depending on vertical space and desired blanking coverage.

For high-density zones or mixed-rack sites, modular panels offer the adaptability to maintain cold aisle continuity across varying formats.

2. Airflow Strategy

Blanking panels are a core component of cold aisle containment. Where airflow recirculation risks are high, particularly near end-of-row racks or in non-standard enclosures, tighter snap-fit panels are essential.

In facilities using raised floors, airflow behaviour may also benefit from integration with directional tiles or brush grommets to fully isolate conditioned airflow paths.

3. Installation Flexibility

For facilities undergoing frequent MACs or incremental hardware shifts, tool-free installation becomes a functional requirement. EziBlank’s ergonomic snap-on design ensures panels can be deployed or repositioned without tools, saving time and avoiding rack damage.

Facilities seeking a permanent fit, such as colocation cages or fixed server suites, may combine modular panels with optional Universal Catch clips for long-term anchoring.

Installation & Maintenance Best Practices

While blanking panels are simple to install, consistent performance depends on attention to alignment, spacing, and periodic review. The following best practices help ensure optimal airflow containment throughout the panel’s lifecycle:

Installation Guidelines

- Align panels flush with the rack frame to prevent micro-gaps

- For mixed-height units, install larger panels at the bottom to improve visual consistency and airflow stacking

- Use only snap-on tool-free panels in high-change environments to avoid tool wear or stripped threads

- When integrating with Tailor-Made Airflow Solutions, coordinate panel positioning with aisle zoning and pressure differential planning

Maintenance Recommendations

- Inspect quarterly for dislodged or loose panels, particularly after hardware changes

- Clean using a microfiber cloth to remove dust and debris buildup that may affect seal contact

- Recycle or replace any panel showing structural fatigue, cracks, or improper fit

- Reassess panel placement during any rack reconfiguration to avoid unused airflow paths or thermal leaks

When paired with thermal monitoring platforms such as EkkoSense, panel performance can be reviewed visually through airflow maps, making it easier to identify missed zones or excess bypass air.

Conclusion: Design for Reuse, Deploy for Efficiency

Blanking panels are not passive accessories; they are precision-engineered components that shape the performance, appearance, and sustainability of every rack environment. When chosen carefully and deployed with intent, they offer measurable returns in energy efficiency, operational savings, and environmental impact.

EziBlank panels reflect this ethos. Their modular, snap-on design, tool-free ergonomics, and durable construction make them a foundational element in data centre airflow strategy, from enterprise halls to hybrid cloud edge nodes.

To explore which configurations best align with your infrastructure goals, visit our Modular Blanking Panels or speak directly with our airflow engineers.

Efficiency begins with every RU. Design smarter airflow with EziBlank. Contact Us for a custom lifecycle assessment.

Frequently Asked Questions

What is the typical lifespan of a reusable blanking panel?

EziBlank modular panels are designed for over 1,000 snap-in cycles without compromising structural integrity or airflow sealing. Their ABS construction ensures long-term performance in dynamic rack environments.

How do blanking panels improve cooling efficiency in data centres?

Blanking panels seal open rack units (RUs), preventing hot exhaust air from recirculating into the cold aisle. This preserves front-to-back airflow paths and reduces unnecessary load on CRAC units.

Are reusable blanking panels recyclable at the end of their life?

Yes. EziBlank panels are manufactured from UL-94 V0 flame-retardant ABS plastic, which supports responsible recycling. Facilities can also participate in approved take-back programs for compliant disposal.

What size options are available for modular blanking panels?

Panel sizes include 1U through 10SU, compatible with 19”, 21”, and 23” racks, following EIA-310-D and ETSI standards. This range supports full or partial blanking in both enterprise and edge environments.

How is ROI calculated for reusable panels?

Return on investment can be evaluated by comparing panel replacement frequency, cooling energy savings, and reduced downtime. When deployed alongside EkkoSense AI Optimization, real-time airflow improvements can further enhance measurable ROI.