Choosing the right blanking panels is one of the most cost-effective ways to improve airflow management and energy efficiency in your data centre. Yet, many operators overlook how much server rack configuration, mounting type, and material quality matter when selecting a blanking panel solution.

This guide will walk you through everything you need to know to make the best choice for your environment. Whether you manage an enterprise data centre, a hyperscale facility, or a compact edge deployment.

What Are Blanking Panels and Why Are They Important?

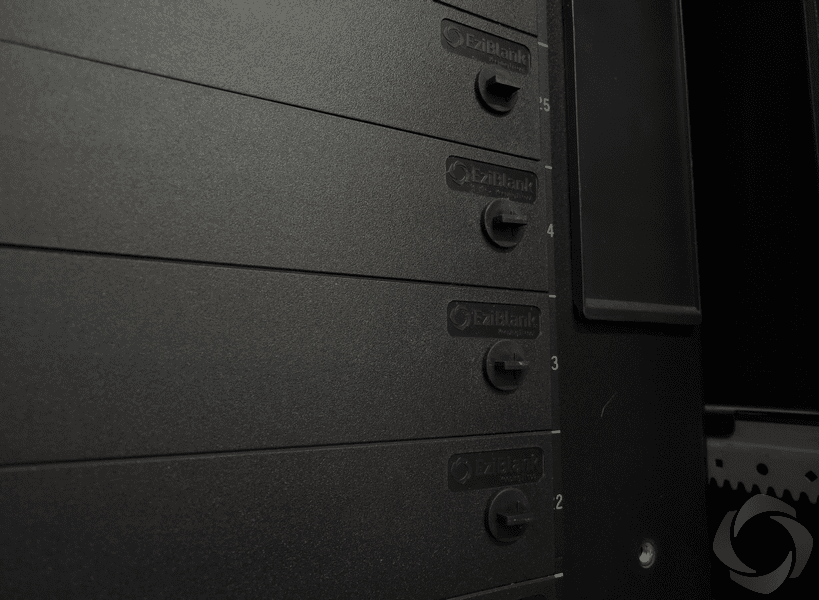

Blanking panels are modular plates installed in unused rack units (RUs) within server cabinets to block the recirculation of hot air. This ensures that cold air from the front of the server rack configuration reaches active equipment without being mixed with hot exhaust air from the rear.

Poor airflow containment can lead to:

- Localized hotspots

- Increased fan speed and power usage

- Reduced equipment lifespan

- Unnecessary cooling costs

As explored in our post on airflow management mistakes, neglecting blanking panel use often leads to degraded cooling performance and higher operational expenses.

1. Assess Your Server Rack Type and Size

The first step is knowing your server rack’s standard. Most racks follow the EIA-310-D 19” format, but there are also 21” ETSI racks and 23” telecom racks commonly used in regional and legacy setups.

EziBlank offers purpose-built blanking panels for each server rack configuration:

Key tip: Always verify if your racks use square or round mounting holes, as this will impact the panel’s compatibility.

2. Choose Modular Over Fixed Panels for Flexibility

Modular blanking panels allow you to snap off sections to match the exact RU space you want to fill. This means you don’t need to carry a large inventory of 1RU, 2RU, or 4RU units.

EziBlank’s patented snappable design enables:

- Faster deployment across varied server rack configurations

- Reuse of partial panels when hardware changes

- Reduction in waste and storage complexity

Unlike rigid fixed panels, modular panels adapt to your evolving rack layout, saving you time and long-term replacement costs.

3. Evaluate the Mounting Method

Look for tool-free, universal mounting systems that reduce installation time and risk. Older panels often require screws or special fasteners, which increase complexity and make future adjustments harder.

EziBlank panels feature:

- Precision-moulded clips for square hole rails

- Knob latches made from medical-grade thermoplastic elastomer for smooth locking

- Alignment studs to ensure secure fit during installation

For more flexible mounting, Rackstuds™ can be used with 19”, 21”, and 23” blanking panels or brush panels, simplifying installation in live environments.

4. Understand Material Quality and Safety Ratings

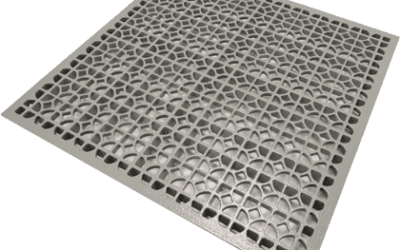

Not all panels are built the same. Material choice impacts fire safety, durability, and long-term usability.

EziBlank panels are made from:

- UL94-V0 flame-retardant ABS plastic – certified for use in mission-critical data centres

- Scratch-resistant textured surface – maintains appearance and protects from wear

- Recyclable lightweight plastic – lowers shipping cost and supports sustainability

These features aren’t just nice-to-haves. Poor material choices can contribute to airflow contamination and create safety liabilities.

5. Match Panel Design to Aesthetic & Functional Needs

In today’s enterprise environments, aesthetics matter. Choosing panels that integrate seamlessly with the look and layout of your server rack configuration reflects operational professionalism.

EziBlank’s cohesive design philosophy ensures:

- Colour-matched options for different server rack configurations

- Smooth textures that blend into cabinet facades

- Minimalist fittings that don’t interfere with other equipment

Additionally, choosing branded panels like EziBlank means better lifecycle support, from spare catches to replacement parts designed for field upgrades.

6. Factor in Airflow Strategy: Hot Aisle or Cold Aisle?

Depending on your data centre layout, your panel selection may differ:

- Cold aisle containment: Ensures cold air flows only to active equipment

- Hot aisle containment: Prevents hot air from re-entering the intake zone

Blanking panels are particularly effective when used in tandem with floor grommets, brush panels, or containment walls. For instance:

- 1RU Brush Panels help seal cable entries

- Flex Brush Panels close gaps under racks

- EziBlank Wall Systems create full rack-to-ceiling containment

Combining these solutions leads to measurable PUE improvement and reduced cooling load.

7. Consider Environment: New Builds vs Retrofits

If you’re working on a new build, modular tool-free panels are ideal for rapid deployment and future-proofing.

For retrofits in live environments:

- Use snappable, low-resistance panels like the 6RU Universal Panel

- Opt for brush-based panels for cable-heavy areas

- Avoid panels that require back-panel access or additional hardware

Every second spent installing panels in a live environment introduces risk — make tool-free and ergonomic choices to minimize it.

Final Thoughts: Maximize ROI with the Right Blanking Panel

Blanking panels may seem like a minor infrastructure component, but their impact on cooling efficiency and operational cost is substantial. By choosing the right panel for your server rack configuration, airflow needs, and installation environment, you protect your equipment, lower your energy bills, and extend the life of your data centre infrastructure.

At EziBlank, we’ve helped operators across six continents make smarter airflow decisions. Whether you’re planning a new deployment or retrofitting an existing facility, our range of modular blanking panels is designed to adapt, perform, and protect.

Frequently Asked Questions About Choosing Blanking Panels

1. What size blanking panel do I need for my server rack configuration?

You’ll need to match the blanking panel to your rack’s standard and the number of unused rack units (RUs). Most data centres use 19” EIA-310-D compliant racks, but 21” (ETSI) and 23” racks are also common. Modular panels like the EziBlank® 6RU let you snap off segments to fit 1RU, 2RU, or more, offering maximum flexibility for various rack heights.

2. Are tool-free blanking panels better than screw-mounted ones?

Yes. tool-free blanking panels like EziBlank’s snappable designs significantly reduce installation time and risk, especially in live environments. They also allow for easy repositioning and reusability as your server rack configuration changes, unlike fixed panels which are slower to install and more rigid.

3. Do blanking panels really improve data centre efficiency?

Absolutely. Blanking panels prevent hot exhaust air from recirculating into the cold aisle, reducing hotspots and helping cooling systems work more efficiently. This leads to lower fan usage, better airflow targeting, and improved PUE (Power Usage Effectiveness), especially when combined with brush panels and containment systems.

4. What’s the difference between modular and fixed blanking panels?

Modular blanking panels can be snapped into smaller sections to fit different RU gaps, while fixed panels come in specific sizes (e.g., 1RU or 2RU). Modular designs offer better scalability, easier storage, and cost efficiency since fewer panel sizes are needed to cover multiple gaps.