Next-gen blanking panels may not be the flashiest data center hardware, but they play a critical role in maintaining efficient airflow. Traditionally, these simple filler panels covered empty rack spaces to prevent hot air recirculation. Today, next-gen blanking panels are anything but ordinary, they come packed with innovative designs that make them easier to install, more adaptable, and more effective at improving cooling. From tool-less mounting systems to modular layouts and smart materials that enhance airflow, the humble blanking panel has evolved into a high-tech component of modern data centers. EziBlank, as a leader in airflow management, has been at the forefront of these innovations, offering some of the most next-gen blanking panels solutions in the industry. Here we explore the latest advancements in blanking panel design and functionality, and how EziBlank’s innovative approach is setting new standards.

Tool-Less Designs for Fast Deployment

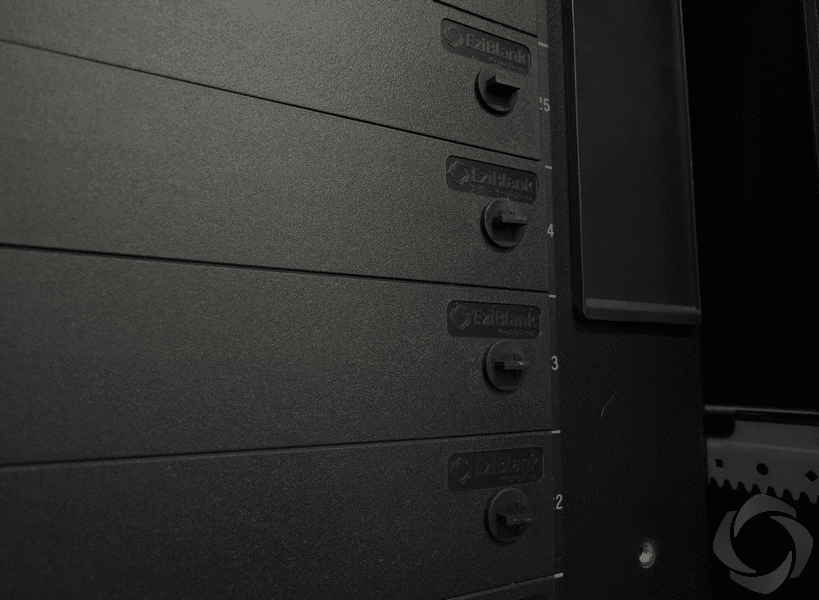

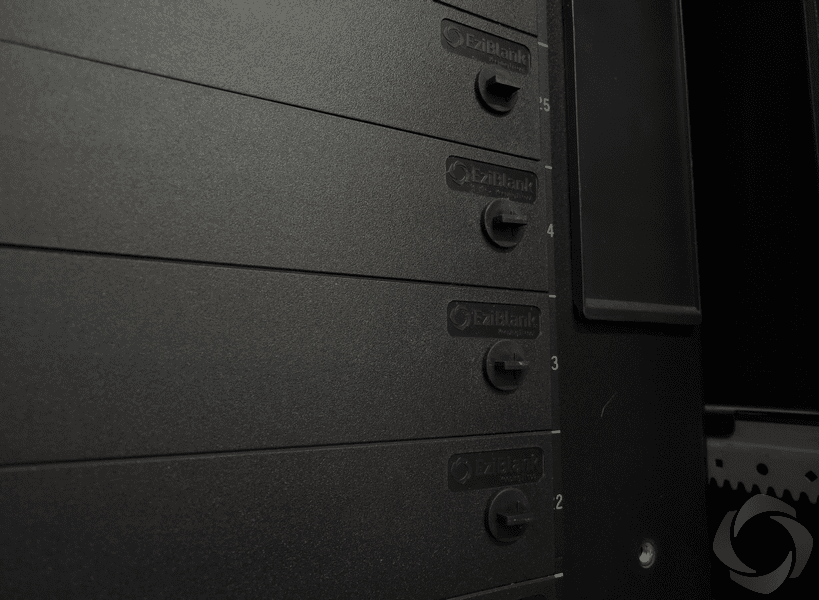

EziBlank’s tool-free blanking panels snap into place with an innovative clip design, allowing quick installation by hand without any screws or tools. next-gen blanking panels often feature tool-less mounting mechanisms that make installation a breeze. In the past, technicians had to secure blanking panels with screws, requiring time and a screwdriver for each panel. Next-gen blanking panels designs eliminate that hassle completely. Snap-in clips and quick-release tabs now let you install or remove a panel in seconds, no tools needed. This tool-free approach means data center staff can reconfigure rack layouts on the fly. If you add or move servers, blanking panels can be popped out or repositioned without any downtime or tedious unscrewing. The benefit is not only speed, but also reduced risk of error or overtightening (since no screws are involved). The Next-gen blanking panelsmount securely yet release easily, striking a perfect balance. In fast-paced IT environments, like cloud and hyperscale data centers where hardware changes are frequent, quick-deploy next-gen blanking panels save valuable time and effort. EziBlank’s tool-less design exemplifies this innovation, ensuring that maintaining proper airflow is as simple as “snap in and go” for any technician.

Modular Panels for Flexible Fit

A modular 6U blanking panel can be snapped into smaller sections, allowing a perfect fit for any combination of open rack units. Another major innovation in blanking panel design is the move toward modular, adjustable panels. Instead of using a handful of fixed-size panels (like only 1U or 2U pieces) to cover various gaps, next-gen blanking panels are often larger units that can break into smaller sections as needed. EziBlank pioneered this approach with its 6U blanking panel system – a single panel that can cover a large six-unit opening or be snapped apart into individual 1U increments to cover scattered spaces. This snappable design gives data center operators tremendous flexibility. You can mix-and-match sections from one panel to plug any size gap in your server racks, all without having to keep dozens of different panel sizes on hand. For example, if you have a 4U empty space in one rack and a 2U space in another, a single 6U modular panel can be separated to fill both, no need to purchase separate panels for each. This adaptability simplifies inventory and ensures you always have the right size panel available. It also means fewer unused next-gen blanking panels sitting around, the modular pieces can be reused across different racks and configurations, reducing waste. Importantly, modular panels maintain a tight seal at every size. EziBlank’s design uses clever features like knob latches and alignment studs so that whether the panel is used as 6U or split into smaller sections, it fits securely and covers the space without gaps. The result is an incredibly versatile next-gen blanking panels system, one product that adapts to virtually any rack layout. By embracing modular panels, data centers can achieve optimal airflow even as equipment arrangements change, all while using a consistent, compatible solution across their infrastructure.

Advanced Materials and Smart Airflow Management

Next-gen blanking panels are not only about clever layouts and easy installation, they also leverage advanced materials to improve performance and durability. Next-gen blanking panels use high-tech plastics and composites that are engineered for the data center environment. For instance, many Next-gen blanking panels today are made from flame-retardant ABS polymer or similar materials, which means they meet strict fire safety standards and can withstand high temperatures without deforming. This is crucial in hot aisle conditions, a panel that won’t warp or crack over time will continue to block airflow leakage effectively for years. These advanced plastics are also lightweight yet strong, making panels easy to handle during installation while ensuring they’re tough enough for long-term use.

In fact, next-gen blanking panels often come with a host of material advantages that collectively contribute to better airflow management and longevity. For example, modern blanking panels typically offer:

- Flame-Retardant & Heat-Resilient Build: Constructed from materials like ABS, they resist fire and tolerate extreme rack temperatures without warping. This guarantees that the panels maintain a tight seal and do their job even in the hottest conditions.

- Lightweight, Durable Construction: Advanced thermoplastics provide high impact resistance and strength while keeping the panel lightweight. The panels won’t crack under pressure and can endure repeated installations, all while being easy to mount and remove.

- Universal Compatibility: High-precision molding and material stability enable a universal fit on standard racks. The panels have built-in positioning studs and adjustable catches that accommodate any 19-inch rack mount holes (whether square, round or threaded). The material’s slight flexibility helps the panel conform snugly to different rail types, truly making it “one size fits all.”

- Eco-Friendly & Reusable Design: Many of these panels are designed with sustainability in mind. The ABS plastic used by EziBlank is not only recyclable but also reusable through multiple upgrade cycles. High-quality materials mean the same panel can be installed, removed, and installed again over years without degrading. By choosing durable, recyclable materials, data centers reduce waste and support green initiatives while optimizing cooling.

Overall, these smart material choices directly impact airflow effectiveness. A sturdy, well-fitted panel made of quality plastic creates a reliable barrier that keeps cold air in the front of the rack and hot air in the back. There are no unintentional gaps or sagging over time, so the airflow path remains controlled as intended. Some cutting-edge next-gen blanking panels even explore intelligent design tweaks, to ensure virtually no air leakage around the next-gen blanking panels. The combination of material science and design refinement results in next-gen blanking panels that are far more than simple pieces of plastic. They become a carefully engineered part of the cooling ecosystem, actively contributing to lower temperatures and higher efficiency. By using high-performance, resilient materials, EziBlank have transformed next-gen blanking panels into long-lasting, “set-and-forget” solutions that continuously improve airflow management in the data center.

Next-Gen Blanking Panels

Next-gen blanking panels has undergone a remarkable transformation. What used to be a plain filler plate is now a next-generation airflow tool with tool-less mounting, modular sizing, and advanced materials that significantly boost cooling efficiency. These innovations in design and functionality mean easier installation, greater flexibility, and more reliable performance in keeping hot and cold air separated. EziBlank has been a driving force in this evolution, combining smart design features (like easy installation and modular panels) with proven airflow benefits to create next-gen blanking panels engineered for the data centers of tomorrow. By investing in next-gen blanking panels, organizations can ensure their racks run cooler and their cooling systems work smarter, not harder.

Ready to experience the benefits of next-generation blanking panels in your own facility? EziBlank invites you to explore our latest next-gen blanking panels range and see how these innovative designs can transform your data center’s airflow and efficiency. From tool-less, snap-in panels to adaptable modular solutions, EziBlank’s lineup demonstrates why we’re leaders in blanking panels innovation. Don’t let your cooling potential go to waste, check out EziBlank’s Next-gen blanking panels today and discover a smarter way to manage airflow in your racks!